Difference between revisions of "EPU452 Manual"

(→RTD commands) |

(→Hardware Warranty) |

||

| (25 intermediate revisions by 2 users not shown) | |||

| Line 14: | Line 14: | ||

# '''Biosensor''', for amperometric sensors, incuding enzymic peroxide sensors. | # '''Biosensor''', for amperometric sensors, incuding enzymic peroxide sensors. | ||

| − | |||

This manual also describes the operation of: | This manual also describes the operation of: | ||

| Line 65: | Line 64: | ||

=== MF Configurator Software === | === MF Configurator Software === | ||

Menu Items | Menu Items | ||

| − | File: | + | :• File: |

| − | Open – this opens a folder containing previously named saved configurations | + | :• Open – this opens a folder containing previously named saved configurations |

| − | Save – this saves the current configuration for future use. | + | :• Save – this saves the current configuration for future use. |

| − | Save as.. – this saves a configuration with a new name | + | :• Save as.. – this saves a configuration with a new name |

Help: | Help: | ||

| − | User Manuals | + | :• User Manuals |

| − | Software update options | + | :• Software update options |

| − | Check for updates- checks to see if you are running the latest version of software. | + | :• Check for updates- checks to see if you are running the latest version of software. |

| − | About…. Describes the version of MF Configurator software installed | + | :• About…. Describes the version of MF Configurator software installed |

Unit Set-Up Screen | Unit Set-Up Screen | ||

The unit setup screen allows three important actions to be performed: | The unit setup screen allows three important actions to be performed: | ||

| Line 110: | Line 109: | ||

==== General Commands ==== | ==== General Commands ==== | ||

| − | |||

{| style="width: 85%;" | {| style="width: 85%;" | ||

| − | | style="width: | + | | style="width: 30%; | '''Command''' || style="width: 70%;" | '''Description''' |

|- | |- | ||

|help '''?''' ||List commands | |help '''?''' ||List commands | ||

| Line 167: | Line 165: | ||

|set channel <N> function Cond ||Configure channel as conductivity <N> = 1, 2, 3, 4 or 'all' | |set channel <N> function Cond ||Configure channel as conductivity <N> = 1, 2, 3, 4 or 'all' | ||

|} | |} | ||

| + | |||

| + | |||

| + | Note1: Channel can be abbreviated to '''c''' | ||

==== Voltmeter (mV) commands ==== | ==== Voltmeter (mV) commands ==== | ||

{| style="width: 85%;" | {| style="width: 85%;" | ||

| − | | style="width: | + | | style="width: 30%; | '''Command''' || style="width: 70%;" | '''Description''' |

|- | |- | ||

|help '''?''' ||List commands | |help '''?''' ||List commands | ||

| Line 193: | Line 194: | ||

==== pH and Ion Selective meter commands ==== | ==== pH and Ion Selective meter commands ==== | ||

{| style="width: 85%;" | {| style="width: 85%;" | ||

| − | | style="width: | + | | style="width: 30%; | '''Command''' || style="width: 70%;" | '''Description''' |

|- | |- | ||

|set channel <N> range <value>||Set input range (2000, 200) mV | |set channel <N> range <value>||Set input range (2000, 200) mV | ||

| Line 228: | Line 229: | ||

====Conductivity commands==== | ====Conductivity commands==== | ||

{| style="width: 85%;" | {| style="width: 85%;" | ||

| − | | style="width: | + | | style="width: 30%; | '''Command''' || style="width: 70%;" | '''Description''' |

|- | |- | ||

|set channel <N> range <value> ||Set input range (200, 20, 2, 0.2, 0.02, 0.002, 0.0002) mS/cm | |set channel <N> range <value> ||Set input range (200, 20, 2, 0.2, 0.02, 0.002, 0.0002) mS/cm | ||

| Line 250: | Line 251: | ||

|calc channel <N> tds <TDS> ||Take a reading and calculate the tds factor to give the specified TDS value | |calc channel <N> tds <TDS> ||Take a reading and calculate the tds factor to give the specified TDS value | ||

|- | |- | ||

| − | |set channel <N> offset <0 | + | |set channel <N> offset <0 off> ||Remove any input offset |

|- | |- | ||

|set channel <N> offset auto ||Automatically zero the input. | |set channel <N> offset auto ||Automatically zero the input. | ||

| Line 260: | Line 261: | ||

|get channel <N> function ||Get the channel's current function | |get channel <N> function ||Get the channel's current function | ||

|} | |} | ||

| − | + | ||

====Thermistor commands==== | ====Thermistor commands==== | ||

{| style="width: 85%;" | {| style="width: 85%;" | ||

| − | | style="width: | + | | style="width: 30%; | '''Command''' || style="width: 70%;" | '''Description''' |

|- | |- | ||

|set channel <N> range <value>||Set input range (125, 75) °C | |set channel <N> range <value>||Set input range (125, 75) °C | ||

| Line 273: | Line 274: | ||

|get channel <N> ohms ||Take a single reading in ohms | |get channel <N> ohms ||Take a single reading in ohms | ||

|} | |} | ||

| − | + | ||

====RTD commands==== | ====RTD commands==== | ||

{| style="width: 85%;" | {| style="width: 85%;" | ||

| − | | style="width: | + | | style="width: 30%; | '''Command''' || style="width: 70%;" | '''Description''' |

|- | |- | ||

| − | |set channel <N> range ||Set input range -20 | + | |set channel <N> range ||Set input range -20 to 500°C |

|- | |- | ||

|get channel <N> range ||Get input range | |get channel <N> range ||Get input range | ||

| Line 286: | Line 287: | ||

|get channel <N> ohms ||Take a single reading in ohms | |get channel <N> ohms ||Take a single reading in ohms | ||

|} | |} | ||

| − | + | ||

====dO2 commands==== | ====dO2 commands==== | ||

{| style="width: 85%;" | {| style="width: 85%;" | ||

| − | | style="width: | + | | style="width: 30%; | '''Command''' || style="width: 70%;" | '''Description''' |

|- | |- | ||

|set channel <N> range <value> ||Set input range (2000000, 200000, 20000, 2000, 200, 20)nA or, 2mA, 200uA, 20uA, 2uA, 200nA, | |set channel <N> range <value> ||Set input range (2000000, 200000, 20000, 2000, 200, 20)nA or, 2mA, 200uA, 20uA, 2uA, 200nA, | ||

| Line 305: | Line 306: | ||

|set channel <N> Vex <millivolts> ||Set Vex in millivolts | |set channel <N> Vex <millivolts> ||Set Vex in millivolts | ||

|- | |- | ||

| − | |get channel <N> Vex ||Get Vex | + | |get channel <N> Vex ||Get Excitation voltage Vex |

|- | |- | ||

| − | |set channel <N> offset <0 | + | |set channel <N> offset <0 off> ||Remove any input offset |

|- | |- | ||

|set channel <N> offset auto ||Automatically zero the input. | |set channel <N> offset auto ||Automatically zero the input. | ||

| Line 319: | Line 320: | ||

|cal channel <N> set <n> <current> ||Take a reading and use as calibration point number n, at the specified value | |cal channel <N> set <n> <current> ||Take a reading and use as calibration point number n, at the specified value | ||

|- | |- | ||

| − | |cal channel <N> remove <n | + | |cal channel <N> remove <n all> ||Remove the nth, or all calibration points |

|- | |- | ||

|cal channel <N> get ||Show calibration information | |cal channel <N> get ||Show calibration information | ||

|} | |} | ||

| − | + | ||

====Biosensor commands==== | ====Biosensor commands==== | ||

{| style="width: 85%;" | {| style="width: 85%;" | ||

| − | | style="width: | + | | style="width: 30%; | '''Command''' || style="width: 70%;" | '''Description''' |

|- | |- | ||

|set channel <N> range <value> ||Get input range | |set channel <N> range <value> ||Get input range | ||

| Line 340: | Line 341: | ||

|set channel <N> Vex <millivolts> ||Set Vex in millivolts | |set channel <N> Vex <millivolts> ||Set Vex in millivolts | ||

|- | |- | ||

| − | |get channel <N> Vex Get Vex | + | |get channel <N> Vex ||Get Excitation voltage Vex |

|- | |- | ||

| − | |set channel <N> offset <0 | + | |set channel <N> offset <0 off> ||Remove any input offset |

|- | |- | ||

|set channel <N> offset auto ||Automatically zero the input. | |set channel <N> offset auto ||Automatically zero the input. | ||

| Line 354: | Line 355: | ||

|cal channel <N> set <n> <current> ||Take a reading and use as calibration point number n, at the specified value | |cal channel <N> set <n> <current> ||Take a reading and use as calibration point number n, at the specified value | ||

|- | |- | ||

| − | |cal channel <N> remove <n | + | |cal channel <N> remove <n all> ||Remove the nth, or all, calibration points |

|- | |- | ||

|cal channel <N> get ||Show calibration information | |cal channel <N> get ||Show calibration information | ||

| − | |||

| − | |||

|} | |} | ||

| − | + | ||

====Advanced settings commands==== | ====Advanced settings commands==== | ||

A number of advanced commands are available to users providing their own operating software. Contact eDAQ for support. | A number of advanced commands are available to users providing their own operating software. Contact eDAQ for support. | ||

| − | + | ====Sampling rates==== | |

| − | The | + | |

| − | + | The '''s''' sample command will show readings at 1Hz (the default), or a rate that you can optionally specify. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | There are a limited number of sampling rates available ('''get rates''' lists available rates for a specific function. | |

| + | The valid rates available may depend on what functions and ranges are assigned to the channel. | ||

| + | Conductivity is special case, in that sampling rates also depend on the range being used. | ||

| + | Sampling can only occur at a speed common to all channels. | ||

| + | Maximum sampling rate is 100s/Sec. | ||

| + | |||

| + | If multiple functions are active, then only the lowest common sample rate that all the channels "agree upon" will be used. In the example below, if conductivity channel is chosen to operate at 10 samples per second, then the mV channel will also operate at 10 /s. | ||

| + | |||

| + | An example showing the different rates available for mV compared to mid-range conductivity: | ||

EPU452> set c 4 func mv | EPU452> set c 4 func mv | ||

| Line 384: | Line 387: | ||

Channel 4 range 0.02 | Channel 4 range 0.02 | ||

EPU452> get rates | EPU452> get rates | ||

| − | EPU452 Rates 1 2 4 5 10 20 | + | EPU452 Rates 1 2 4 5 10 20 |

| − | + | ||

| − | + | ||

==Specifications == | ==Specifications == | ||

| Line 496: | Line 497: | ||

=== Hardware Warranty === | === Hardware Warranty === | ||

| − | eDAQ Pty Ltd warrants this product, to be free of defects in material and workmanship for | + | eDAQ Pty Ltd warrants this product, to be free of defects in material and workmanship for 12 months from the date of purchase. eDAQ Pty Ltd will repair or replace defective equipment as appropriate. To obtain a warranty repair/replacement you must first notify us before return of the instrument and we will issue you with a RAN (return authorisation number). You must ship the defective product at your expense. We will pay return shipping. The product should be packed safely (preferably in its original packaging) and have the RAN on the shipping label. Returns sent without a RAN may be refused delivery. |

This warranty does not cover hardware that has: | This warranty does not cover hardware that has: | ||

Latest revision as of 16:23, 27 June 2018

Contents

Introduction

The Quad MF isoPod (model number EPU452) is a four–channel, miniature amplifier/interface that connects to a Windows XP or later computer via a USB port or hub. Each of its four channels (Ch 1, Ch 2, Ch 3, and Ch 4, Figure 1) can be independently configured to one of seven possible functions:

- mV, a general purpose high impedance millivolt monitor;

- pH, a pH meter mode. Also suitable for ion selective electrodes (ISE's) and oxidation/reduction potentiometric (ORP) electrodes.

- Conductivity, for two-electrode solution conductivity probes.

- RTD, precalibrated for 1000 ohm platinum RTD temperature probes

- Thermistor, precalibrated for 30 kohm thermistor temperature probes

- dO2, for Clark–style polarographic oxygen electrodes.

- Biosensor, for amperometric sensors, incuding enzymic peroxide sensors.

This manual also describes the operation of:

- • the MF Configurator software, used to set up the system, and

- • the embedded serial protocol, which is required if you intend to write your own data acquisition and display software, or interact manually with the isoPod by issuing typed commands using terminal emulation software.

Please see the separate Pod-Vu software manual to learn about collecting and displaying signals without any additional programming!

Checking the Instrument

Before you begin working with the device, you should check:

- • that the contents of the package you received match the packing list

- • for any sign of physical damage that might have occurred during transit.

If you find a problem, please contact your eDAQ distributor or agent immediately.

Quick installation

- Install the MF Configurator and Pod-Vu application software on your computer using the USB memory stick provided. This will also ensure the correct software drivers are installed.

- See the Help menu of the application for directions to any software updates.

- Power the MF isoPod by connecting it to the 5 V DC mains adaptor supplied.

- Connect the MF isoPod unit to the computer using the USB cable provided.

- For first use, run the MF Configurator software to select the function and set the parameters of each channel.

- Attach appropriate sensor probes to each of the isoPod channels.

- You can now run the Pod-Vu software to collect and display data, or start writing your own data recording software.

CAUTION: Make sure that only a compatible sensor is attached to each channel.

Placement of the wrong sensor on a channel (eg connecting a pH electrode to a dO2 recording channel) may damage the probe. Both the MF Configurator software utility and Pod-Vu recording software will display the device configuration.

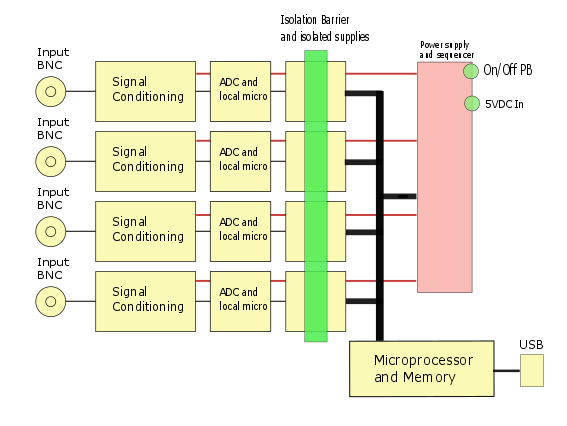

System Description

This system consists of four independently isolated, reconfigurable, signal conditioning and measuring circuits connected to a microprocessor which communicates with a Windows XP or later computer via a USB port Figure 2. Sensors are connected using the front panel low–leakage BNC input connectors. The signal on each channel is converted to a digital data stream by a precision 24 bit analog to digital converter (ADC). The data is passed to a master microprocessor across an electrical isolation barrier for processing and transmission via a USB port to the computer for display and storage. Each of the four channels input can be independently configured as:

- • Voltmeter (mV)

- • pH/mV and Ion Selective Electrode (ISE) meter

- • Solution Conductivity meter

- • RTD Temperature meter (0 – 450°C)

- • Thermistor Temperature meter (0 – 75, or 0 – 125°C)

- • Dissolved Oxygen meter (dO2)

- • Biosensor meter (for amperometric/polargraphic probes)

by use of the MF Configurator software (included).

Operating Software

The system is provided with two support applications:

- • Pod-Vu software which enables Windows computers to calibrate, collect, and display signals. Up to eight isoPods channels (i.e. two Quad MF isoPod units can be connected simultaneously for monitoring eight probes) can be graphically displayed at speeds up to 1 sample per second. Data can be copied and pasted to other software applications for further analysis or reporting, or saved in text format which can be read by spreadsheet or word processor software. Channels need to be configured to suit user requirements using the MF Configurator prior to use with Pod-Vu. The operation of Pod-Vu is described in the separate Pod-Vu manual.

- • MF Configurator software utility is provided with the system and enables channel functions to be configured and sensors tested and calibrated. This utility must be installed prior to using the Quad MF isoPod. Once the channels are configured the isoPod will remember the settings and perform in this mode every time the system is subsequently powered up, until the system is reset by using the MF Configurator.

MF Configurator Software

Menu Items

- • File:

- • Open – this opens a folder containing previously named saved configurations

- • Save – this saves the current configuration for future use.

- • Save as.. – this saves a configuration with a new name

Help:

- • User Manuals

- • Software update options

- • Check for updates- checks to see if you are running the latest version of software.

- • About…. Describes the version of MF Configurator software installed

Unit Set-Up Screen The unit setup screen allows three important actions to be performed:

- • Assign a function, from those available, to each Channel

- • Select the range, decimal places and calibration for each channel function.

- • Display sensor data for checking and calibration purposes.

Paul D– should we add a description of each different range/calibration panel? No but you do need one for each function (pH, conductivity etc) (PD)

Serial Protocol

This serial protocol is stored within the isoPod unit and can be used with any suitable terminal emulation software (for example Tera Term) to communicate with the EPU452. With a terminal program installed and set up correctly with the EPU452 connected via the USB port to the PC, the system will respond to a set of commands described in here.

Establishing serial communications

With the ER452 connected and powered up communication with the computer can be established. A suitable terminal emulation software application must be installed. Serial Ports 1 and 2 on Windows computers are reserved for the mother board. It is therefore common to find that the EPU452 or other serial devices are assigned automatically to serial port 3 (COM3) or greater. Use your Terminal software to configure the virtual serial port as shown below (based on the use of Tera Term). Serial port item is then selected from the Tera Term Settings menu item in order to setup the serial port.

Select COM port to which the ER452 is connected.

The virtual serial port should then be configured as:

- • 115200 baud

- • 8 bits

- • 1 stop bit

- • parity set to none

- • Flow control set to NONE

Commands

Once the serial port is set up, type in a ? to get a listing of the available commands listed in Appendix X. An ‘enter’ will produce an ER452> prompt requesting one of the protocol commands.

This protocol can also be used by other applications such as:

- • LabVIEW™

- • WinWedge®

- • Tera Term or

- • with your own software written in Visual Basic, or C++, etc.

General Commands

| Command | Description |

| help ? | List commands |

| version | Get firmware version |

| blink | Blinks/flashes Power LED to confirm communications |

| beep | Beeps to attract attention |

| s sample [Hz] | Sample at specified rate (see Note 1 below), 1Hz default |

| get rates | Get available sample rates on selected channel |

| i interval <seconds> | Interval sampling (slow sampling) |

| r | Take a single reading |

| adc | Get raw ADC voltage values |

| prompt <on> <off> | Enable or disable the command prompt |

| get functions | Get a list of available channel functions |

| get settings | Get list of current channel functions |

| set name | Set device name |

| get name | Get device name |

| get serial | Get device serial number |

| set channel <N> dp <n auto> | Set the number of decimal places <N> = 1, 2, 3, 4 or 'all' |

| get channel <N> dp | Get the number of decimal places <N> = 1, 2, 3, 4 or 'all' |

| get channel <N> function | Get the channel's current function <N> = 1, 2, 3, 4 or 'all' |

| set channel <N> function Off | Disable channel <N> = 1, 2, 3, 4 or 'all' |

| set channel <N> function mV | Configure channel as mV <N> = 1, 2, 3, 4 or 'all' |

| set channel <N> function pH | Configure channel as pH <N> = 1, 2, 3, 4 or 'all' |

| set channel <N> function RTD | Configure channel for Pt 1000 ohm RTD probe <N> = 1, 2, 3, 4 or 'all' |

| set channel <N> function Therm | Configure channel for 30 kohm Thermistor probe <N> = 1, 2, 3, 4 or 'all' |

| set channel <N> function dO2 | Configure channel as dO2 <N> = 1, 2, 3, 4 or 'all' |

| set channel <N> function Bio | Configure channel as biosensor <N> = 1, 2, 3, 4 or 'all' |

| set channel <N> function Cond | Configure channel as conductivity <N> = 1, 2, 3, 4 or 'all' |

Note1: Channel can be abbreviated to c

Voltmeter (mV) commands

| Command | Description |

| help ? | List commands |

| version | Get firmware version |

| set channel <N> range <value> | Set input range(2000, 200, 20)mV |

| get channel <N> range | Get input range |

| get channel <N> ranges | Get available ranges |

| set channel <N> offset <0 off> | Remove any input offset |

| set channel <N> offset auto | Automatically zero the input. |

| set channel <N> offset <mV> | Set the offset to the specified amount |

| get channel <N> offset | Return the current offset level |

pH and Ion Selective meter commands

| Command | Description |

| set channel <N> range <value> | Set input range (2000, 200) mV |

| get channel <N> range | Get input range |

| get channel <N> ranges | Get available ranges |

| get channel <N> units | Return the current units name |

| set channel <N> units <name> | Set the units reported when doing a reading |

| set channel <N> units | Revert to default units |

| cal channel <N> start <T> | Use ideal response from Nernst formula, for pH calculations (n=1), at the specified temperature |

| cal channel <N> start <T> <n> <E0> | Use Nernst equation, as above, but with a specific ion charge, and E0 |

| cal channel <N> set <n> <pH> | Take a reading and use as calibration point number n, at the specified pH |

| cal channel <N> set <n> <pH> <mV> | Set calibration point number n, with the specified pH and mV reading |

| cal channel <N> remove <n all> | Remove the nth, or all, calibration points |

| cal channel <N> get | Show calibration information |

| calcph channel <N> <voltage> | Calculate pH for specified voltage |

| calcv channel <N> <pH> | Calculate voltage for specified pH |

| mtc channel <N> <degC> <IsoPotV> | Set the temperature for making readings (MTC). Optionally override the default isopotential of 0V |

Conductivity commands

| Command | Description |

| set channel <N> range <value> | Set input range (200, 20, 2, 0.2, 0.02, 0.002, 0.0002) mS/cm |

| get channel <N> range | Get input range |

| get channel <N> ranges | Get available ranges |

| set channel <N> range [freq] [amp] | Set range with optional frequency (Hz) and amplitude (mV) values |

| get channel <N> k | Get the k value |

| get channel <N> tds | Get the tds value |

| set channel <N> k <value> | Sets the k value of the conductivity probe. If k is set to 0 then raw conductances (G) are reported, otherwise conductivity (kappa) values are reported |

| set channel <N> tds <value | Set the tds factor. If tds is set to 0 then raw conductances (G) are reported, otherwise tds is reported (in ppm) |

| calc channel <N> k <kappa> | Take a reading and calculate the correct k to give the specified conductivity value |

| calc channel <N> tds <TDS> | Take a reading and calculate the tds factor to give the specified TDS value |

| set channel <N> offset <0 off> | Remove any input offset |

| set channel <N> offset auto | Automatically zero the input. |

| set channel <N> offset <mS> | Set the offset to the specified amountS |

| get channel <N> offset | Return the current offset level |

| get channel <N> function | Get the channel's current function |

Thermistor commands

| Command | Description |

| set channel <N> range <value> | Set input range (125, 75) °C |

| get channel <N> range | Get input range |

| get channel <N> ranges | Get available ranges |

| get channel <N> ohms | Take a single reading in ohms |

RTD commands

| Command | Description |

| set channel <N> range | Set input range -20 to 500°C |

| get channel <N> range | Get input range |

| get channel <N> ranges | Get available ranges |

| get channel <N> ohms | Take a single reading in ohms |

dO2 commands

| Command | Description |

| set channel <N> range <value> | Set input range (2000000, 200000, 20000, 2000, 200, 20)nA or, 2mA, 200uA, 20uA, 2uA, 200nA, |

| get channel <N> range | Get input range |

| get channel <N> ranges | Get available ranges |

| get channel <N> units | Return the current units name |

| set channel <N> units <name> | Set the units reported when doing a reading |

| set channel <N> units | Revert to default units |

| set channel <N> Vex <millivolts> | Set Vex in millivolts |

| get channel <N> Vex | Get Excitation voltage Vex |

| set channel <N> offset <0 off> | Remove any input offset |

| set channel <N> offset auto | Automatically zero the input. |

| set channel <N> offset <amount> | Set the offset to the specified current |

| get channel <N> offset | Return the current offset level |

| get channel <N> res | Take a reading and calculate resistance |

| cal channel <N> set <n> <current> | Take a reading and use as calibration point number n, at the specified value |

| cal channel <N> remove <n all> | Remove the nth, or all calibration points |

| cal channel <N> get | Show calibration information |

Biosensor commands

| Command | Description |

| set channel <N> range <value> | Get input range |

| get channel <N> ranges | Get available ranges |

| get channel <N> units | Return the current units name |

| set channel <N> units <name> | Set the units reported when doing a reading |

| set channel <N> units | Revert to default units |

| set channel <N> Vex <millivolts> | Set Vex in millivolts |

| get channel <N> Vex | Get Excitation voltage Vex |

| set channel <N> offset <0 off> | Remove any input offset |

| set channel <N> offset auto | Automatically zero the input. |

| set channel <N> offset <amount> | Set the offset to the specified current |

| get channel <N> offset | Return the current offset level |

| get channel <N> res | Take a reading and calculate resistance |

| cal channel <N> set <n> <current> | Take a reading and use as calibration point number n, at the specified value |

| cal channel <N> remove <n all> | Remove the nth, or all, calibration points |

| cal channel <N> get | Show calibration information |

Advanced settings commands

A number of advanced commands are available to users providing their own operating software. Contact eDAQ for support.

Sampling rates

The s sample command will show readings at 1Hz (the default), or a rate that you can optionally specify.

There are a limited number of sampling rates available (get rates lists available rates for a specific function. The valid rates available may depend on what functions and ranges are assigned to the channel. Conductivity is special case, in that sampling rates also depend on the range being used. Sampling can only occur at a speed common to all channels. Maximum sampling rate is 100s/Sec.

If multiple functions are active, then only the lowest common sample rate that all the channels "agree upon" will be used. In the example below, if conductivity channel is chosen to operate at 10 samples per second, then the mV channel will also operate at 10 /s.

An example showing the different rates available for mV compared to mid-range conductivity:

EPU452> set c 4 func mv Channel 4 configured as mV EPU452> get rates EPU452 Rates 1 2 4 5 8 10 20 25 40 50 100

EPU452> set c 4 func cond Channel 4 configured as Cond EPU452> set c 4 range 0.02 Channel 4 range 0.02 EPU452> get rates EPU452 Rates 1 2 4 5 10 20

Specifications

- • Number of Channels: 4

- • Input connectors: Teflon insulated BNC connectors on front panel.

- • Available configurations:

- • Voltmeter (mV)

- • pH and Ion Selective Electrode meter

- • Conductivity meter

- • RTD Temperature meter

- • Thermistor Temperature meter

- • Oxygen meter (dO2)

- • Biosensor Amperometric meter

- • Channel function individually configurable with software

- • Operating Temperature: -10°C to 50°C

- • Protection: +/-15V

- • Isolation: Minimum 2500V isolation from system ground all channels individually isolated from ground and from each other.

- • Maximum input voltage: 250 V @ 50 or 60 Hz

- • Maximum sampling rate: 100 s/s on each channel

- • ADC resolution: 24 Bits

- • Digital connection: USB with virtual serial port

- • COM port setting: 115200 baud; 8 bits; 1 stopbit; no parity; flow control NONE

- • Operating temperature: 0 – 45°C

- • Power: 5 V DC external power, <100 mA at start up, <500 mA in operation.

- • Dimensions w x h x d: 130 x 35 x 185 mm

- • Weight: 500g

- • Indicators:

- • Power On LED Blue,

- • Online/active Green/flashing green LED

Voltmeter - mV

- • Voltage Input ranges:

- ±2000 mV with Gain error 0.01%

- ±200 mV Gain error < 0.2%

- ±20 mV with Gain error < 0.2%

- • Input impedance: >1012 ohms || 4 pF

- • Input leakage current: <30 fA @25°C

- • DC temperature drift: <5 µV/°C

- • DC Offset Error: < 1 mV

- • Resolution: < 10 uV

- • Noise: < 5 uV RMS at 10 /s

pH– Ion Selective electrodes

- • pH Input range:

- > 0 - 14 pH on ±2000 mV range with Gain error < 0.01%

- 3.6 – 10.4 pH on ±200 mV range with Gain error < 0.2%

- • Input impedance: > 1013 ohms || 4 pF

- • Input leakage current: < 30 fA @ 25°C

- • DC temperature drift: < 5 µV/°C

- • DC Offset Error: < 1 mV

- • Resolution: < 10 µV or 0.0001 pH

- • Noise: < 5 uV RMS at 10 /s

Conductivity

- • Conductivity ranges: 200 mS, 20 mS, 2 mS, 200 µS 20 µS, 2 µS

- • Gain error:

- < 1% FS on 200 mS and 2 uS ranges

- < 0.1% on other ranges.

- • Excitation source: Square Wave 0 - 200 mVp-p 10 Hz to 10 kHz

- • Noise: < 0.01% at 1 /s

- • Temperature drift: < 0.01%/°C Negligible compared to solution temperature TC.

RTD Temp

- • Temperature probe: 1000 Ohm Pt RTD eg. ET021

- • Temperature range: -20 to 500°C

- • Accuracy: ±(0.10 + n/600)°C, where n = temperature in °C

- • Resolution: 0.001°C

- • Offset error: < 0.1% of FS

- • Noise: < 0.1% of FS at 1 /s

- • Temperature drift: <0.01% of FS/°C

Thermistor

- • Temperature probe: 30 kohm Thermistor eg. ET020

- • Temperature ranges: -10 to 75°C and -25 to +125°C

- • Accuracy: ±0.2°C

- • Resolution: 0.001°C

- • Offset error: <0.1% of FS

- • Noise: <0.1% of FS at 1 /s

- • Temperature drift: <0.01% of FS/°C

dO2

- • Current Input Range: 20uA,2uA,200nA,20nA

- • Resolution: >1:1,000,000

- • Polarization Range: -1000 mV

- • Polarization resolution: 1mV

- • Offset Range: +/-20µA

- • Noise: <1pA RMS at 1 /s

Biosensor

- • Current Input Range: 20uA, 2uA, 200nA, 20nA

- • Resolution: >1:1,000,000

- • Polarization Range: –2000 to +2000 mV

- • Polarization resolution: 1mV

- • Offset Range: +/-20µA

- • Noise: <1pA RMS at 1 /s

Legal and Warranty

Trademarks and Copyright

isoPod, Quad MF isoPod, Pod-Vu, and MF Configurator are trademarks of eDAQ Pty Ltd. Windows XP, Vista, and Windows 7, Windows 8 and Windows 10 are trademarks of Microsoft Corporation. This document is Copyright © July 2015. This document, or sections thereof, may be copied by the owners or users of an eDAQ Quad MF isoPod for their private use. Otherwise no part of this document may be reproduced by any means without the prior written permission of eDAQ Pty Ltd.

Responsibilities

You and any others using any eDAQ product agree to use it in a sensible manner for purposes for which it is suited, and agree to take responsibility for their actions and the results of their actions. If problems arise with an eDAQ product, eDAQ will make all reasonable efforts to fix them. This service may incur a charge, depending on the nature of the problems, and is subject to the other conditions in this Agreement.

Hardware Warranty

eDAQ Pty Ltd warrants this product, to be free of defects in material and workmanship for 12 months from the date of purchase. eDAQ Pty Ltd will repair or replace defective equipment as appropriate. To obtain a warranty repair/replacement you must first notify us before return of the instrument and we will issue you with a RAN (return authorisation number). You must ship the defective product at your expense. We will pay return shipping. The product should be packed safely (preferably in its original packaging) and have the RAN on the shipping label. Returns sent without a RAN may be refused delivery.

This warranty does not cover hardware that has:

- • been modified by the user in any way;

- • been subjected to unusual physical, electrical, or environmental stress. This includes damage due to faulty power sockets, inadequate earthing, or power spikes or surges;

- • been damaged because of incorrect wiring to ancillary equipment, or because of substandard, connectors or cables; or

- • had the original identification marks removed or altered.

Software License

You have the non-exclusive right to use the supplied eDAQ software (Pod-Vu, MF Confiurator etc). Your employees or students, for example, are entitled to use it, provided they adhere to this agreement.

computers, more than two copies must not be used simultaneously. Departmental/company licences are available if you wish to run more than two copies simultaneously.

Technical Support

Please register your unit to receive technical support.

Technical assistance is available via email. Please describe the problem with as much detail as possible. Include a small example data file, if appropriate. Please also state:

- • the model and serial number of your EDAQ system.

- • the type of computer and operating system being used (for example Windows XP, Vista, Windows 7, 8, or 10)

- • the software version you are using (for example Chart v5.5.2)

We endeavor to answer all your questions, but in some cases, for example where the problem relates to the other equipment that you are using, a nominal fee may be charged.

Jurisdiction

eDAQ Pty Ltd is bound by the laws of New South Wales in Australia, and any proceedings shall be heard by the Supreme Court of New South Wales in Australia.

Disclaimer

eDAQ reserves the right to alter specifications of hardware and software without notice. No liability can be accepted for consequential damages resulting from use of eDAQ products.