ER430 Manual

Contents

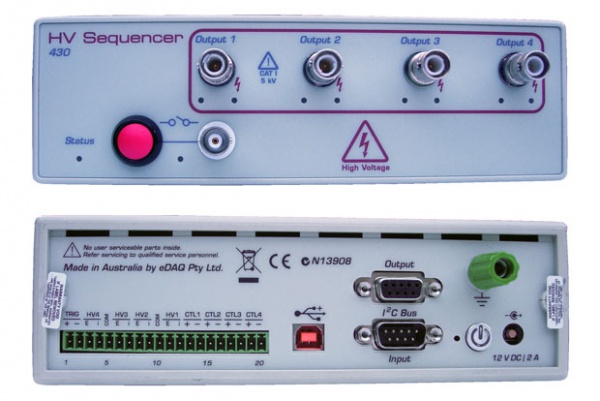

Introduction

This manual is intended to allow the user to install, check and run the ER430 HV Sequencer. It provides detailed information on the system and its operation. Please read this manual carefully prior to beginning operation.

The ER430 High Voltage Sequencer provides the following functions:

- • Four independent programmable metered high voltage (HV) supplies.

- • Safety Interlock system

- • Software that allows arbitrary sequences of voltages to be generated

Checking the Instrument

Before you begin working with the device, you should check:

- • that the contents of the package you received match the packing list

- • for any sign of physical damage that might have occurred during transit.

If you find a problem, please contact your eDAQ distributor or agent immediately.

Safety First

This equipment generates high voltages of up to 3000 V DC at currents of up to 200 µA. Making contact with such voltages can be extremely dangerous.

Ensure that the high voltage (HV) circuits are housed in an insulated enclosure fitted with an Interlock safety circuit and with no manual access to HV circuits while circuits are alive.

Safety precautions:

- • Ensure that the safety interlock circuit is connected to the HV Sequencer and is only active and enabled when no accidental access to High Voltage circuits can be made.

- • Wear rubber soled footwear

- • Ensure the floor and bench top are dry

- • Stand on a rubber mat when in the vicinity of high voltages

The ER430 features design precautions to ensure that there is no accidental application of high voltages. These include automatic shutdown in the event of voltage or current overloads . This will in some circumstances prevent the unit from operating. In these cases check all settings and safety interlocks carefully before resuming the experiment.

What is an Interlock

An interlock is a mechanical or electrical system that prevents the inadvertent operation of of an instrument.

In the case of the ER430 HV Sequencer this is achieved by using a switch located in the customer provided enclosure in which high voltages are active. This switch is connected via a cable to the front panel INTERLOCK BNC in such a way that the switch is only closed when no access is available to the High voltages inside the enclosure.

For example with the eDAQ supplied ET225 Micronit Chip Electrophoresis Platform, high voltages can only be applied when the top cover is in place. This is detected and the interlock switch enabled to allow the application of high voltages.

If the user is providing the MicroChip enclosure then it is the user’s responsibility to provide the required interlock function.

To test the Interlock function it is sufficient to apply a short circuit across the INTERLOCK BNC input pins. This should only be done with no connections to the High Voltage input connectors.

System Indicators

System indicators as shown in the preceding diagram provide a direct indication of system operation that reflects the state of the internal hardware. These indicators will assist you in monitoring system operation and in diagnosing problems – study them carefully:

INTERLOCK LED (Amber LED)

- • FLASHING = Interlock open, unit disarmed, arming not enabled.

- • OFF = Interlock in place and enabled, unit can be ARMED.

- • ON = Interlock in place, unit armed and ready for operation.

SYSTEM STATUS LED (RGB LED)

- • GREEN when “on line” and ready as a Master

METER FUNCTION LED (RGB LED)

- • GREEN: Safe (disconnected)

- • YELLOW: Current Mode

- • BLUE: Voltage mode

HV STATUS (RED LED)

- • OFF: supply disconnected

- • ON: supply connected and active.

Notes:

- On power up the system performs a startup test and flashes the front panel LEDs through the various colors available for display.

- In some cases where the HV supply needs to be used in proximity to light sensitive detectors it is possible to optionally turn off all the LEDs to maintain low background illumination.

Hardware Installation

ATTENTION: When installing the system for the first time ALWAYS perform software installation before connecting the hardware units. This ensures that the correct drivers are installed.

After carrying out the software installation described in the next section, perform the following Hardware installation procedure. It will confirm that:

- • That safety interlocks are in place and functioning correctly

- • The unit can be armed and disarmed

Unit Operation

- • Safety first: Connect the unit to a good ground using the terminal post on the rear of the unit.

- • Connect the unit to the 12V DC mains power pack.

- • Connect the unit to the PC using the USB cable provided.

- • Turn Power on.

INTERLOCK LED will flash if interlock is not enabled.

HV Status LEDs: Off (no high voltage output)

STATUS LEDs: Green

TEST INTERLOCK Function

This function can be tested without any software running:

- • The INTERLOCK LED will initially be flashing.

- • Connect a short circuit to the INTERLOCK BNC.

- • INTERLOCK LED will turn OFF.

- • Press the ARM Push Button for approximately 1 to 2 seconds. You should hear a beep, warning you that the HV outputs have been armed (enabled) and the INTERLOCK LED will turn ON.

- • At this point all HV supplies are still inactive but are in a state where they can be set and controlled by the Sequencer Application software.

- • Pressing the Arm button again will DISARM the HV Sequencer, and the INTERLOCK LED will turn off.

A momentary push on the Arm button will disable all the HV outputs of the Sequencer.

INTERLOCK features

The system is provided with a number of safety features or Interlocks:

- • Chip adapter interlock: The chip adapter used should provide a safety contact interlock to indicate that the microchip adapter is safe for use. This interlock is a contact closure switch, which is closed when the HV circuit is fully enclosed and protected from user access. This interlock is connected to the front panel Interlock BNC and indicates to the ER430 that it is safe to arm the system.

- • USB Present: The system cannot be ARMED without an active USB connection

- • Software Control: Once the system is ARMED High Voltages can only be applied under software control.

- • ARM circuit: prior to applying HV to an external circuit the system must be armed by the user by depressing the front panel ARM push button for approximately 2 seconds.

- • DISARM: The system can be disarmed by a momentary push of the ARM button.

- • Power Overloads: the circuit detects power overloads and situations that lead to the generation of arcs (sparks). The system will switch itself off in such circumstances and in such circumstances may require to be reinitiated with power being turned Off and On.

!!CAUTION!! Do not disconnect HV leads by hand while High voltages are present – this is extremely dangerous and can cause harmful arcs to be generated. To disable power use the ARM/DISARM front panel button or the software’s Disarm or Disconnect menu items

You are now ready to operate the Sequencer software which will allow you to generate and output a series of high voltage pulses and ramps.

Software Installation & Operation

Installing the HV Sequencer software

Insert the HV Sequencer installation USB stick into your computer. It is recommended to install the software before plugging in the hardware, as this ensures the drivers are correctly installed.

The eDAQ Sequencer Setup Wizard will display a start-up screen; follow the prompts to install the software.

Start up screen

Final Start up screen

eDAQ Sequencer Overview

eDAQ Sequencer is a Windows application that provides the means to setup a series of steps that are executed under computer control. The following functions are provided:

System setup and sequence entry: The software identifies system configuration on startup and allows the operating parameters to be set immediately.

Table driven Sequence: A time based table is filled out, specifying that the operations to be performed in sequence. This includes setting of HV supplies to new voltages, trigger and digital I/O line functions. The following sequence operations are implemented:

Time: set to xxxx seconds

Output 1 to 4: Set V=xxxx (V and I monitored), Read V, Read I

Meter Function: Disconnect HV and set Voltmeter or Current mode

Digital Out: Low/Open, High/Closed, Short Pulse, Long Pulse

Special commands: Wait for trigger, Wait for Arming, Go Safe

New functions can be readily added to meet customer requirements

Digital outputs can be used to control external devices or the recording of data in an ecorder.

Monitoring: Once a sequence is started the user is able to observe the progress of the sequence on the sequence table. Values of HV supply voltages and currents are displayed during operation.

HV Sequencer Main Window

Communication

The HV sequencer uses a virtual USB serial communications (COM) port. When the ER430 hardware is first attached to USB, a free COM port number is automatically assigned by Windows. That COM port will be then used every time that unit is plugged in again.

Note: the first time you connect the system to the computer it may take some time for the system to identify the HV sequencer device driver and install it. You will be notified when the device is ready.

The first time you use the sequencer software, you need to specify the COM port that the hardware has been assigned. Select the Preferences option in the File menu, then choose your HV Sequencer in the list at the top – see screen shot below. This preference is automatically saved for future use

Preferences panel

If you are uncertain about which COM port to assign use, the Serial Port Monitor application can help identify the COM port assigned to the HV sequencer. This small application is included on the HV Sequencer installer USB stick, and can also be downloaded from the eDAQ Utilities and Tools download webpage

www.edaq.com/utilities_tools.php

The serial port monitor runs as an icon in the notification area. Clicking on it will show a list of eDAQ COM port devices attached to your computer.

The other Preference options set the digital output type, and provide control over front panel lights in situations where light pollution needs to be kept to a minimum.

Check if you have installed an interlock as described previously. The INTERLOCK LED should be OFF indicating that the INTERLOCK is in place.

Online panel

Click the Online in the menu bar to attach the selected ER430 unit to the Sequencer application.

Click the Offline in the menu bar to disconnect the selected ER430 unit from the Sequencer application.

Offline panel

Disarming and Interlock Test

Press and hold the red ARM button to arm the unit. As before, the unit will beep and arm itself. This will also be shown in the software’s display.

You can now disarm the unit by either:

- • Pressing the red ARM button again

- • Clicking “Disarm” in the top-right of the software window.

While the unit is armed, you can test the safety interlock by removing the short-circuit from the BNC connector. The unit should immediately disarm itself, disconnecting the outputs, and turning off any applied voltages.

Manual Settings

After arming the unit, click on the More… button to display the controls for making immediate changes to the unit.

The right hand side of the HV Sequencer setup panel provides the means to manually set meter functions, output voltages, and the digital outputs’ states. Make some selections, and then click on Set. The ER430 hardware will immediately apply the settings you have chosen, and the software will display your choices, along with readings of current and/or voltage.

At this point the system will indicate the voltages set and currents measured. Since no loads are yet connected, the currents will be very near zero.

ER430 Sequencer setup panel

At any time, pressing the Disarm button in the top-right hand corner of the Main Window or the red button on the front panel of the ER430 will disarm the unit and make it safe.

After disarming, you must press and hold the red button (as before) to re-arm it. The software can not re-arm the device.

Outputs let you control the digital outputs of the unit. In the preference you can set Output configuration as contact closure, or TTL.

HV Sequences

The lower area of the Setup panel provides the means to define a “program” or “sequence” to run. This consists of a number of timed steps, each of which can update the state of one or more of the individual functions or outputs. There are also some “special” commands that can be carried out. Unused connections can have the width of their columns reduced by dragging their column separator.

All changes on a step happen simultaneously (within 2 milliseconds).

Setup screen with an example

Here is another example program:

Setup screen with an example

If a step doesn’t have anything entered in its box, the output will remain unchanged from its previous setting.

A time of “0” means “immediately upon starting”, and the times are cumulative, measured from when the sequence was started, i.e.: the delay between the first four of the lines above is 5, 3, and 4 seconds respectively.

It is recommended to have the first row setting every output to a known state, in case the previous run was stopped part-way through, leaving the unit in an unknown state.

When the program finishes, the unit will be left in whatever state it was at the end. It will not automatically disconnect or disarm the outputs, unless explicitly told to do so.

Channel Functions

Each channel can be set to be either to perform as a Meter or as an HV output channel.

Meter channel functions are:

Disconnected: Disconnected from the front panel terminal (LED GREEN)

Read V: Voltmeter connection (LED BLUE)

Read I: Current Meter connection (LED YELLOW

Output channel functions are:

Disconnected: Disconnected from the front panel terminal.

Read V: Voltmeter connection (LED BLUE).

Read I: Current meter connection (LED YELLOW ) Set V: Set the voltage to the value entered in the second column – In this mode the Voltage indicated will be the actual voltage produced within 1%. (LED RED)

Digital outputs can be set to:

Low/Open: Output goes low or open, as per the “digital output mode” setting in Preferences.

High/Closed: Output goes high or closed.

The type of digital output, TTL or Contact Closure, is set from the Preferences dialog in the File menu.

Special is a special function to be performed. There are currently two special functions:

- • Disarm: Disconnect HV supplies, and stop the program, or

- • Wait for trigger: Pause, and wait for a high/close on the rear panel’s 'green' connector “Trigger” pins.

Simple editing commands are available on the Edit menu.

Programs can be saved and loaded using the menu options in the File menu.

Once you are satisfied with your program, click the Run button in the menu bar. The software will step through the program, executing each step at the given time after starting.

Sequencer operating bar

The Pause button can be used to pause running of the program. The Run button changes to a Resume button, which you can click to continue execution.

Stop will stop execution, but it will leave the unit in the current state, with whatever voltages selected still being output.

The Disarm button will stop any running program and put the ER430 hardware into a safe state.

Various fault and safety switch conditions will also force a disarming (and termination of program), including:

• USB cable being removed

• Front panel safety interlock opened/removed

• Front panel red button being pressed

• When operating with a slave unit, disconnection from the slave unit

Modes of Operation

General

- • Disarmed/Safe – High voltages and meters disconnected

- • Armed- High voltages are active and available for connection to external circuit.

Programmable HV power supplies

Output Voltage: Adjustable from ±200V to ±3000V at up to 200µA. Output Polarity: Positive or Negative with respect to the common ground potential

Operating Modes

- • O/C mode: Open Circuit by disconnection with high voltage relay.

- • Voltage Mode: High voltage output mode with current and voltage monitoring

- • HiZ Mode: Voltage monitoring – 100 Megohm impedance

- • S/C Mode: Short circuit to ground with current monitoring

Meters

- • O/C mode: Open Circuit achieved by disconnection with high voltage relay

- • HiZ Mode: Voltage monitoring – 100 Mohm impedance

- • S/C Mode: Short circuit to ground with current monitoring

By combining the HV power supplies and meters it is possible to setup the conditions which load the sample into the separation channel and then apply the appropriate voltages to cause separation and detection of the sample components as shown in the example.

Typical Installation

ER430 HV Hardware

ER430 HV Channel Block Diagram

A Block diagram of a HV supply channel is shown below; there are four identical HV channels in each ER430unit:

ER430 Meter Channel block diagram

Green Connector Pin Numbers

| Pin No | Pin Label | Description | Pin No | Pin Label | Description |

|---|---|---|---|---|---|

| 1 | TRIG + | TTL in | 11 | HV1 E | HV VOLTAGE MONITOR 1 |

| 2 | TRIG - | TTL COM | 12 | HV1 I | HV CURRENT MONITOR 1 |

| 3 | HV4 E | HV VOLTAGE MONITOR 4 | 13 | CTL1 + | DIGITAL IN/OUT 1 |

| 4 | HV4 I | HV CURRENT MONITOR 4 | 14 | CTL1 - | DIGITAL COM |

| 5 | COM | COMMON/GND | 15 | CTL2 + | DIGITAL IN/OUT 2 |

| 6 | HV3 E | HV VOLTAGE MONITOR 3 | 16 | CTL2 - | DIGITAL COM |

| 7 | HV3 I | HV CURRENT MONITOR 3 | 17 | CTL3 + | FF |

| 8 | HV2 E | HV VOLTAGE MONITOR 2 | 18 | CL + | DIGITAL COM |

| 9 | HV2 I | HV CURRENT MONITOR 2 | 19 | CTL - | FF |

| 10 | COM | COMMON | 20 | DD | DIGITAL COM |

- 6 HV3 E HV VOLTAGE MONITOR 3 16 CTL2 - DIGITAL COM

- 7 HV3 I HV CURRENT MONITOR 3 17 CTL3+ DIGITAL IN/OUT 3

- 8 HV 2 E HV VOLTAGE MONITOR 2 18 CTL3 - DIGITAL COM

- 9 HV 2 I HV CURRENT MONITOR 2 19 CTL4 + DIGITAL IN/OUT 4

- 10 COM COMMON 20 CTL4 - DIGITAL COM

Notes:

- Digital I/O pins are implemented as contact closure or TTL outputs, software selectable

- Trigger input can be a contact closure or TTL input

- HV VOLTAGE MONITOR scale factor: 500mV/kV

- HV Current Monitor Scale factor: 100mV/mA

Specifications

High Voltage Output and Mode Options

- • Channels: 4

- • Maximum Voltage Setting: ±3000 V

- • Minimum Voltage Setting: ±200 V

- • Current: ±150µA max

- • Ripple: 0.1%

- • Operating Modes: Applied voltage, Open Circuit (O/C), and Short Circuit (S/C)

- • Load regulation: <2% specified for 20-90% full load:

- • Rise and Fall times: <5 ms specified for changes within the same polarity regime

- • Mode Change: <100ms due to relay operations, safety and software latency

Note: Output is referred to system common (Case Ground)

Safety Features

An interlock is provided on

- • the mechanical case to ensure that no voltages are present with the case open unless authorized maintenance is in progress.

- • the microchip environment to ensure that accidental contact is not made with the high voltages.

The Arm/disarm switch needs to be held for 2 seconds to arm the system and allow high voltages to become active. Any short contact on the ARM switch will disarm the system.

CAUTION: It is the responsibility of the user to ensure that adequate protection is provided on the equipment provided by the user. eDAQ provides microfluidic chip adaptors with appropriate interlock features.

Meter Functions

- • Voltage Range: ±3000 V

- • Voltage Resolution: 1V

- • Current Range: ±150 µA

- • Current resolution: 0.1µA

Communications and Inputs and outputs terminals

- • Daisy Chain connectors: Twin DB9 connectors allow two (2) ER430 units to be daisy chained together.

- • USB Port: Compatible with USB1 & USB 2 and provides, communications facility to PC’s

- • Output and Meters front panel connectors: SHV (Safe High Voltage) type

- • 20 Way 3.5mm Green screw terminal:

- - Four Digital I/O lines

- - Trigger TTL or CC

- - Four Voltage Monitor signals

- - FourCurrent Monitor signals.

- • System/Chassis Earth terminal: 4 mm screw terminal.

System Indicators

The following LED front panel displays are available:

- • System Status (RGB LED)

- GREEN when “on line”

- • System Status (RGB LED)

- • Interlock (amber LED)

- FLASHING = Interlock open, unit disarmed, arming not allowed.

- OFF = Interlock OK, unit disarmed

- ON = Interlock OK, unit armed and ready for operation.

- • Interlock (amber LED)

- • Meter Function (RGB LED)

- GREEN = Safe (disconnected)

- YELLOW = Current Mode

- BLUE = Voltage Mode

- • Meter Function (RGB LED)

- • HV Supply Function (RGB LED)

- GREEN = Safe (supply disconnected)

- YELLOW = Current Mode

- BLUE = Voltage Mode

- • HV Supply Function (RGB LED)

- • HV Supply Status (RGB LED)

- OFF = supply disconnected

- ON = supply connected and active.

- • HV Supply Status (RGB LED)

Physical

- • Dimensions (w x h x d): 200 x 65 x 250 mm (7.9 x 2.6 x 9.8 inch)

- • Weight: 3.00 kg packed

- • Operating temperature: 0 - 35ºC

- • Humidity: 10 to 80% non condensing

- • Power: 9 - 16 V @ 2 A maximum supplied by mains powered AC/DC converter (supplied)

Legal and Warranty

Trademarks and Copyright

Sequencer, HV Sequencer, and Chart are trademarks of eDAQ Pty Ltd. Windows XP, Vista, and Windows 7, Windows 8 and Windows 10 are trademarks of Microsoft Corporation. This document is Copyright © July 2015. This document, or sections thereof, may be copied by the owners or users of an eDAQ Quad MF isoPod for their private use. Otherwise no part of this document may be reproduced by any means without the prior written permission of eDAQ Pty Ltd.

Responsibilities

You and any others using any eDAQ product agree to use it in a sensible manner for purposes for which it is suited, and agree to take responsibility for their actions and the results of their actions. If problems arise with an eDAQ product, eDAQ will make all reasonable efforts to fix them. This service may incur a charge, depending on the nature of the problems, and is subject to the other conditions in this Agreement.

Hardware Warranty

eDAQ Pty Ltd warrants this device, to be free of defects in material and workmanship for three years from the date of purchase. Note that this does NOT include external cables and electrodes that are subject to 'wear and tear' and manufacturing defects should be reported within 90 days of purchase. eDAQ Pty Ltd will repair or replace defective equipment as appropriate. To obtain a warranty repair/replacement you must first notify us before return of the instrument and we will issue you with a RAN (return authorisation number). You must ship the defective product at your expense. We will pay return shipping. The product should be packed safely (preferably in its original packaging) and have the RAN on the shipping label. Returns sent without a RAN may be refused delivery.

This warranty does not cover hardware that has:

- • been modified by the user in any way;

- • been subjected to unusual physical, electrical, or environmental stress. This includes damage due to faulty power sockets, inadequate earthing, or power spikes or surges;

- • been damaged because of incorrect wiring to ancillary equipment, or because of substandard, connectors or cables; or

- • had the original identification marks removed or altered.

Software License

You have the non-exclusive right to use the supplied eDAQ software (Sequencer, Chart etc). Your employees or students, for example, are entitled to use it, provided they adhere to this agreement. Each separate purchase of the eDAQ software licenses it to be used on two computers, more than two copies must not be used simultaneously. Departmental/company licences are available if you wish to run more than two copies simultaneously.

Technical Support

Please register your unit to receive technical support.

Technical assistance is available via email. Please describe the problem with as much detail as possible. Include a small example data file, if appropriate. Please also state:

- • the model and serial number of your EDAQ system.

- • the type of computer and operating system being used (for example Windows XP, Vista, Windows 7, 8, or 10)

- • the software version you are using (for example Chart v5.5.2)

We endeavor to answer all your questions, but in some cases, for example where the problem relates to the other equipment that you are using, a nominal fee may be charged.

Jurisdiction

eDAQ Pty Ltd is bound by the laws of New South Wales in Australia, and any proceedings shall be heard by the Supreme Court of New South Wales in Australia.

Disclaimer

eDAQ reserves the right to alter specifications of hardware and software without notice. No liability can be accepted for consequential damages resulting from use of eDAQ products.