Measuring the Conductivity of a Liquid in a Pipette Tip

The conductivity of a liquid inside a pipette tip can be measured using the ER818 Octal Contactless Conductivity System.

Contents

Introduction

The ER818 offers a method to measure the conductivity of a liquid inside a pipette tip. This can be integrated into an automated robotic system, which delivers the pipette tip into the Octal headstage. Measuring the conductivity directly in the pipette tip, instead of transferring the liquid to a measuring vessel, has a number of advantages:

- Low sample volumes

- Low sample wastage

- Zero cross-contamination

The system has a conductivity range typically of 100 µS/cm to 10,000 µS/cm (the range is determined by the inner diameter of the sample tube).

The system uses a capacitively-coupled contactless conductivity measurement (C4D). This applies a high frequency signal to an excitation electrode on the outside of the pipette tip. This couples the signal to the sample by capacitive-coupling. A detection electrode, located some distance from the sample, measures the resulting current. The current is proportional to the sample conductivity. The measured quantity will depend on the physical dimensions of the test volume and its conductivity.

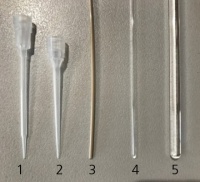

Other possible sample mediums. Typical sample mediums are shown in the figure. All are based on individual samples, except for the 1600 µm outer diameter (OD) capillary, which also allows for a continuous conductivity measurement to be made as the sample flow through the capillary.

1. Straight pipette tip

2. Tapered pipette tip

3. Capillary tubing with 1600 µm OD

4. Melting point disposable glass tube with 1600 µm OD

5. NMR tube with 5 mm OD

Equipment Required

- ER818 Octal Contactless Conductivity System, which includes:

- ER815 Contactless Conductivity Detector

- ET128 Octal headstage

- A computer with Chart software or your own software to record the data (for example, Tera Term, LabVIEW, C#, WinWedge or HyperACCESS)

- Your pipette tips with samples

- A standard solution with conductivity in the middle of the measuring range, say 5 mS/cm

Experiment Procedure

A Quick Start guide describes how to connect the system, how to use Tera Term software to calibrate the system using a standard solution, how to adjust the gain and measure the conductivity of an unknown sample. The Quick Start guide can be downloaded from the manuals webpage.

Notes

Temperature

The volumes of the liquids involved in these measurements are very small and subject to temperature variation. Typically there will be a 4 to 5 °C temperature difference between the ambient laboratory air and the internal temperature of the ET128 Octal headstage. This corresponds to a potential error in conductivity measurement of approximately 5-6%. Since the internal temperature of the headstage is available, temperature compensation can be performed.

Allowing some time for the temperature to equalise can also help in reducing the temperature error. Another approach is to make the conductivity measurement as quickly as possible, before the sample temperature increases.

Use of a Reference Channel

In some applications where small changes in conductivity are to be measured, a reference channel can be used increase the sensitivity of the system and allow for temperature compensation. For example, if the conductivity of the unknown solutions are in the range 2 to 4 mS/cm, a reference solution of 3 mS/cm is selected and placed in the reference channel of the ET128 Octal headstage. This subtracts the reference conductivity value from the unknown solution's conductivity value, so that only the difference is displayed. An advantage of this technique is that any temperature drift in the reference will be removed from the unknown solution, thereby providing temperature compensation.