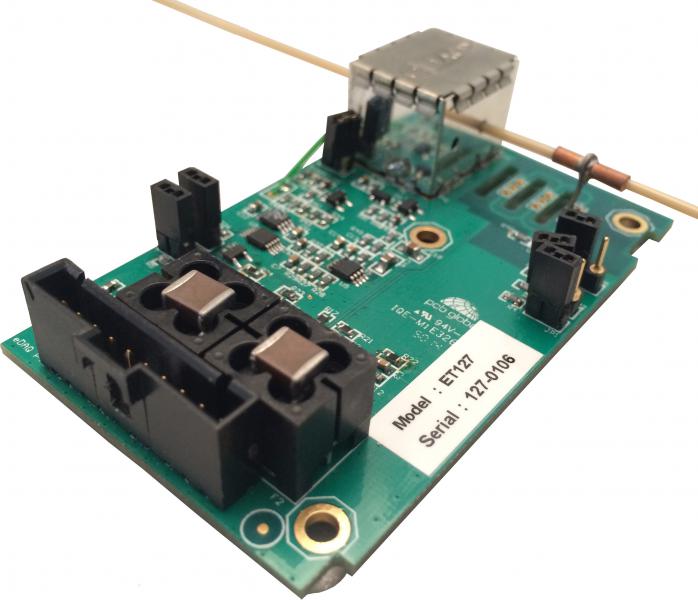

C4DSPL Custom-Made Contactless Conductivity Detectors

C4DSPL Custom-Made Contactless Conductivity Detectors

- Very small sample volumes (nanolitres to millilitres)

- For hazardous, corrosive or radioactive liquids

- Works with different tubing sizes and materials

eDAQ can design and manufacture custom-made instruments to measure the conductivity of a liquid.

With contactless conductivity detection (C4D), the sample doesn't touch the detector electrodes. The liquid can be held in a tube or be flowing through tubing or capillary.

Advantages Of Contactless Detection

- The sample doesn't come into contact with the detector electrodes so it is easy to analyse hazardous, corrosive or radioactive liquids. There is no carryover or memory effect from the previous sample. There is no electrode deterioration or polarization.

- The C4D provides an electrically isolated measurement, which means it won't interfere with other measurements being done in the same liquid.

- Very small sample volumes can be used, less than 20 nanolitres is possible.

Technical

- C4D systems can work with a wide range of tubing diameters. Common outer diameters are 3200 µm (1/8 inch), 1600 µm (1/16 inch), 800 µm (1/32 inch) and 360 µm.

- Many tubing materials can be used with the C4D, including fused silica and plastics like PEEK, PTFE (Teflon) etc. The C4D systems are not compatible with metallic tubing.

- The C4D technique can measure a range of conductivities from 10 µS/cm to 1000 mS/cm.

Previous Customers

Recent projects include the design and manufacture of contactless conductivity detectors/meters for:

- Recording the very low conductivity of arctic melt water, see the application note.

- Measuring liquid-liquid slug flow properties in tubing, see the publication.

- Measuring total dissolved inorganic carbon in seawater with an autonomous oceanic vehicle, see application note and publication.

- A multi-channel C4D detector, which led to the release of the ER825 C4D Detector.